what would cause a power washer motor to overheat

This guide volition testify you exactly how to troubleshoot pressure washer problems.

Including:

- Low h2o pressure

- Water leaking issues

- Engine/motor turning off while in use

- And much more…

But start allow me ask you lot a question:

You ever helped a neighbour gear up something?

Exist careful because once you do – and word gets around – you'll be the go-to-fixit-guy-or-gal for everyone and everything.

Trust me, I know. All my neighbors now know me as the power equipment and force per unit area washer troubleshooting & tune-up guy.

Here's what happens when you're the neighborhood logroller:

4 pm last Saturday I'm in the shed changing pressure washer water pump oil, and over the argue my neighbour says:

"Hey, James, come fix my force per unit area washer and I'll give you a beer."

5 minutes later (beer in paw) he tells me he bought a used pressure washer with water pressure problems…

…It was an electric and started-up fine simply when in-use pulsed out water to get-go, and so later x seconds fell to depression pressure.

My pressure washer troubleshooting experience told me it was air in the pump causing the problem. We switched off the electric motor but kept the water running through the pump. After holding the trigger to keep the water running through the machine we managed to clear the air from the pump and lines. My neighbor turned the car on again and it worked. Full pressure, no pulsing.

Why you lot'll love this beginner'southward guide:

Nothing is worse than a pressure washer that starts upward just won't force per unit area wash properly. You lot go excited hearing it roar to speed only then it doesn't properly clean your surface.

That's why we put together this in-depth power washer troubleshooting guide for you lot… So you tin can ready the problem from your garage – even with zero feel and minimal tools.

Jump to each section:

- Summary of troubleshooting tips

- Instructions for trickier fixes

- 12 essential tools and accessories

- Hot water pressure washer repairs

- Brand specific tips and tricks

- Putting information technology all together

Gas and Electrical Pressure Washer Troubleshooting Tips for 20 of the Most Common Pressure Washer Problems

There are 20 force per unit area washer issues that are by far the most common.

Here'due south how we know what they are:

- Reading 300+ emails from pressure washer users asking for assistance to solve their automobile's problems and counting the occurrences of each fault in an Excel spreadsheet.

- Going through xvi popular pressure washer brands'Operating Manualand tabulating the troubleshooting sections' listed issues and solutions.

- Looking through my power washer logbooks over the last 8 years to see the most mutual issues.

After spending 14+ hours gathering the information the common faults could hands be broken down into 5 sections: H2o force per unit area problems, water leaking issues, gas machine specific problems, electrical pressure washer faults and other common issues. From there the troubleshooting tips are broken down to 3 columns: What'south wrong, most likely cause and how to fix.

Quick note:

- E'er check your Operator'southward Transmission for troubleshooting tips and safety first. Be aware many of the problems have 5 or more possible solutions for yous to try.

Summary Tabular array of Troubleshooting Tips:

The goal of this unabridged page is to brand the about useful pressure washer troubleshooting guide on the internet. We constantly update and better this table. Information technology was last updated July 11, 2020.

Instructions How To Right The Catchy Issues

In this section are instructions how to set up the tricky pressure washer issues, namely the ones that require y'all to tear downwards the pump.

The Lazy Man's Mode to Diagnose Water Pressure (No Force per unit area) Issues

Here'due south the 5 step arroyo to solving 95% of h2o pressure issues in x minutes or less:

- Check h2o supply: Open the water supply valve to total to ensure the pump is getting enough flow.

- Check hose for kinks: I can't tell y'all how many times I've tested a pressure washer, got everything going, just to pull the trigger have information technology not reach pressure. I check the inlet for blocks. I check the nozzle. I check the water is on. And after all these things cheque out and it's all the same not working I turn it off to read through the transmission to discover out what I'm doing wrong. Then, all of sudden, I notice a kink in the hose and realize how much an idiot I was not to detect. I prepare the kink kickoff the automobile and it all works fine. Don't brand this mistake – ever bank check for kinks.

- Release air from organisation: Always connect the garden hose to the power washer starting time. And then turn the h2o tap on and pull the trigger gun to release water from the system at the garden hose water pressure before starting the engine or motor. This will release all the force per unit area from the system and allow the pump to function.

- Ensure correct nozzle and nozzle not clogged:

Use a needle to clear the nozzle tip of whatever debris. Any blocks at the nozzle volition cause decreased menses and increased pressure level in the systems, mayhap triggering the unloader to enter bypass.

Everything You Need to Know About Removing the Unloader Valve to Check for Issues

Unloader valves let water to run through the pump when you are not holding down the trigger on the pressure gun. If there was no unloader valve then pressure would build within the organisation (when not in use) and then when you did pull the trigger it would stall the engine or explode a weak link part – probably the pressure hose o-ring.

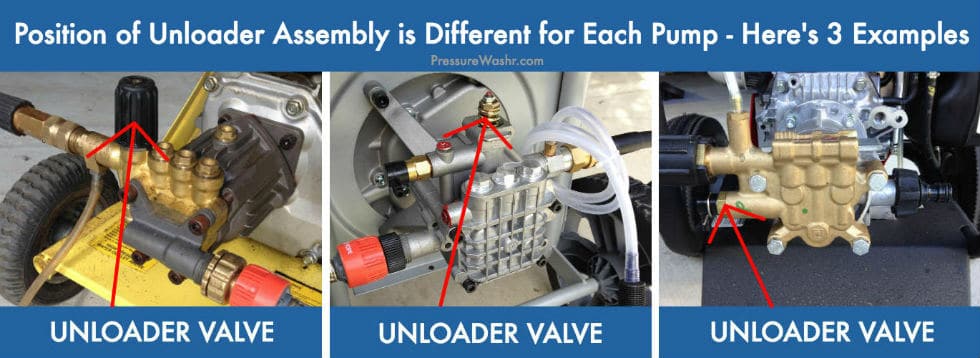

Check out where the unloader is located on iii different pressure washer pumps:

As you can see the unloader is located on the exit side of the pump because it allows the pressurized h2o to flow dorsum through the pump when it isn't exiting into the loftier pressure hose (you lot're not force per unit area washing anything).

Take a wait at two unlike disassembled unloader valve assemblies:

The one on the left is from the Stanley gas pressure washer besides shown in the above prototype on the left. It is a flow actuated unloader.

The unloader on the correct is from an AR Blue Clean electric pressure washer. It is a pressure actuated unloader.

Both these assemblies can be taken out of the pump for cleaning and repair, without damaging them.

The Difference Between Flow and Pressure level Actuated Unloaders

- Menstruum actuated – Equally the name suggests, these unloader valves respond to water flow stoppage. When there is no catamenia leaving the nozzle the valve volition "open up" assuasive water to catamenia back to the pump inlet.

- Pros: Safer because doesn't require pressure level build upward.

- Cons: More sensitive to organization bug similar a clogged nozzle, incorrect nozzle orifice size and other menses problems.

- Pressure actuated – Instead of responding to flow, this blazon of unloader is forced open past an increment in water pressure level allowing water to bypass back to pump inlet (this pressure is increment is usually acquired by period stoppage).

- Pros: Less sensitive to flow issues within the organisation because it responds simply to trapped pressure on the outlet side of the pump.

- Cons: Less safe considering it needs pressure rise to piece of work (could crusade failures within system).

Troubleshooting the Unloader Valve

Many pressure problems brainstorm and end at the unloader. A croaky o-ring, clay caught in the spring or a stuck shaft are the most mutual issues solved past but removing the unloader and cleaning/looking for issues.

12 Essential Tools and Accessories

The 12 below tools are the virtually unremarkably used to repair force per unit area washers.

Tools

Using the below tools I've fully disassembled (all the manner down to removing the gas engine piston seals and crankshaft) and put back together: 3 electrical force per unit area washers and four gas power washers. Allow'due south run through the tools, where they are used and if you lot should buy a complete tool kit or individual tools (and from what tool brands) for repairing your pressure cleaner.

Hex/Allen Keys

These are one of the nigh used tools troubleshooting pressure cleaners because most pump assemblies are fastened together with hex head screws. They are often called Allen caput after the company Allen Manufacturing that started mass producing hex screws and hex wrenches (Allen wrenches/keys) to fasten them in the early on 1900s.

There are three main advantages to hex caput screws:

- Recessed head to brand spiral durable and unlikely to damage.

- Use same hex head on unlike spiral types, sizes and threads (thus just i hex key tool required). These would require several unlike wrenches if they didn't have hex head. This is probable the reason backside their mutual use on bicycles – one hex key minor set up can assistance y'all disassemble and repair your unabridged bike (many dissimilar screw sizes and types only if they all have hex caput you only need your hex keys).

- Torque wrench can be used to tighten them to exact design specification.

Needle-nose Pliers

Needle-nose pliers are very handy because they attain small areas to remove o-rings, seals and valves. I utilize them often when fierce downward a pump to fix h2o force per unit area issues. I also apply them when putting it dorsum together to seat valves and go o-rings and seals into position.

You'll exist very happy to have a set lying effectually when trying to sort out your ability washer faults.

I had a difficult time deciding to put hex keys or needle-nose pliers start considering they are both used oftentimes.

Screwdrivers

Almost the only tool you need to disassemble electrical force per unit area washers is a screwdriver.

Electrical machines' plastic covers – which hibernate the pump and motor – are held together with Philips caput screws.

Gas machines likewise employ Philips – often to clamp downwards wires and get together their frames etc.

In addition, you'll want some slotted screwdrivers to help wedge/drive out certain parts similar pump plunger seals. Torx head screws are also used once you become to the engine block.

Sockets & Ratchet

Every tool ready needs sockets & ratchet and wrenches despite them doing the same thing.

Why?

Considering you can have i ratchet and socket heads for every bolt size in a compact instance. The ratchet allows you to remove or tighten bolts without repositioning and deep socket attachments allow reach to tight spots.

Withal, you besides demand wrenches, especially the open-end side to get to bolts from the side when the top isn't in reach.

Wrenches

Wrenches have been in utilize since the 15th century and are probably the most well-known and owned hand tool.

Many adopt to utilise a ratchet-socket combination because it is quick (don't have to reposition tool when tightening or loosening fastener) and it'south easier to store (and comport effectually) 50+ socket heads instead of 50+ wrenches.

But: When y'all need to get to screws in tight spots you need a wrench. And force per unit area washers have some tight spots.

Rubber Mallet or Hammer

Did you lot know hammers are the oldest known hand tool?

Yup, hammers with handle attached to difficult impacting head have been discovered and dated dorsum xxx,000 years. And nearly verbal replicas of the modern hammer have been plant and dated to around v,000 BC.

They take been useful to humans for 1000s of years – a pretty absurd tool.

While troubleshooting pressure cleaners they are used to gratuitous stubborn parts like the pump head valve plate.

Utility Knife

Cutting tools like knives have been in use nearly equally long as hammers.

They are great aid to troubleshoot faults because they brand quick work removing the detergent hose and assistance wedge under tight fitting components to loosen them. Cutting the soap hose is fine because there's lots of it and y'all'll probably damage it using pliers or other means, anyways.

In addition, you probably own several knives already so no need to get out buying any just to help solve pressure washer bug.

Snips

I like using snips instead of a pocketknife because it's more than precise and quicker.

My snips are sheet-metal snips and cut through tree branches, hoses, and thick plastic or rubber without result. So if you lot burst a pressure washer hose, you could cutting it shorter (with snips) and install the plumbing fixtures instead of buying make new. We did this all the time at a job I had equally a xix year old using a pressure washer to clean a factory parking lot and truck scale every-unmarried-morning.

Snips are a must-own.

Accessories

There'southward no need to go into particular most these accessories. You will 100% want to have silicone grease when you reinstall o-rings, and WD-twoscore, thread tape and grease cleaner will be useful, no incertitude.

What's the Best Tool Set to Get?

The single kit that has everything yous demand to troubleshoot pressure cleaners (except for a prophylactic mallet) is this 170-piece mechanics tool set by Crescent.

You can see that it has:

- Hex keys

- Pliers

- Ratchet + sockets,

- Screwdrivers

- Wrenches

- Snips congenital in to the needle-nose pliers, and

- Conduct instance.

If you don't already own all these hand tools – and you program on fixing your ability washer on your ain – then this is the best tool kit.

See Price on Amazon

Troubleshooting Hot H2o Power Washers

Hot water force per unit area washers can suffer 3 faults:

- No hot water produced

- Besides much/weird color fume out the burner

- No flame from blower.

There'south 15 or so reasons why you may feel these faults and the same number of fixes.

Earlier nosotros become into the fixes, let's acquire more almost the burner components.

How a Pressure Washer Burner Works

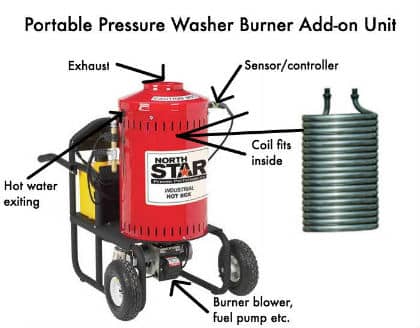

A hot water force per unit area washer has a burner to heat the water. The burner uses diesel fuel or kerosene & air + electricity to generate a burn inside a chamber with water circulating effectually the exterior in tubes coiled like a snake. Water enters at the bottom and by the time it reaches the top – having circulated through all the coil around the flame – exits at the summit as hot h2o.

The burner adds risk/danger to troubleshooting because of the, well, burn down. We recommend you take it to a pressure washer repair middle to get fixed. All the same, there are some simple fixes.

What parts does a pressure washer burner have?

- Steel tubing/coil

- Insulation

- Fuel pump/motor and fuel spray nozzle

- Blower motor

- Electrodes/ignition tranformer

- Thermostat/controller

- Menstruation switch

- Pressure release valve

- Air adjustment slider

- Fuel filter

- Exhaust

Here'southward a 9-minute video to explain everything on burner troubleshooting:

Brand Specific Tips & Tricks for Diagnosing and Fixing Power Washer Issues

Permit's expect at popular brands, the types/styles of pressure washer they brand (including pump brand & type), mutual problems with those pumps and where you can discover further troubleshooting information.

Troy Bilt Troubleshooting Resources

Troy Bilt sells domicile-use medium-duty gas powered machines with AR Blue Clean axial cam pumps.

Briggs & Stratton is Troy Bilt's OEM (original equipment manufacturer) significant Troy Bilt specifies certain things nigh the machine (eg. Honda or Briggs engine) and Briggs makes them in their factories. The Troy Bilt sticker is then placed on the power washer for sale.

A mutual error is that your Troy Bilt will experience no pressure level or low water force per unit area when you lot offset washing. This is often acquired by a dirty or broken unloader valve assembly (run across above tips).

Further information: Troy Bilt Back up Center

Generac

Generac makes and sells residential-utilise medium and heavy-duty machines every bit well every bit belt driven units for commercial use. They have an OEM overseas to manufacture their pumps and engines so assemble them back in their factories in the United states.

Further information: Generac Force per unit area Washer Support Product Lookup

Karcher

Karcher makes all types/styles of force per unit area washers through their own brand and subsidiary brands including Hotsy, Shark and Landa. They are easily the biggest pressure washer maker and seller in the earth. They makes models with all types of the all-time small engines and pumps and accept an all-encompassing rental and service network through their subsidiary brands.

Further information: Karcher Force per unit area Cleaner Knowledgebase

Simpson

Simpson Cleaning sells home and commercial use machines with Kohler, Honda and Simpson OHV engines. The pump brands they use are two in-house brands: OEM Technologies (axial cam) and AAA Pumps (triplex). They also use Cat Pumps brand on some of their premium residential and commercial machines.

Simpson Cleaning are some of the about popular residential gas machines because they offer great value for coin and their pressure washers' wheelbarrow stance is sturdy and much easier to move around compared to the common upright designs.

Common bug include depression or no force per unit area after a few seconds use and soap not entering system properly.

Farther information: Simpson Back up Page

Now What?

If you pressure launder you're bound to need to troubleshoot an issue at some stage. Whether it be no water pressure because of a hose kink or low pressure because of a busted o-ring inside the unloader…

…information technology will happen eventually – merely since you fabricated information technology this far you will accept the cognition to sort your trouble out from your garage – with minimal tools and time.

To decrease the risk of having major issues, accept a look at the 7 all-time for home use – these are the all-time designed and least likely to neglect.

Okay, to wrap up: Let's review the gist of the tips outlined in this guide:

- Water pressure problems (no, depression and/or sporadic water pressures): Check water supply is on full and no hose kinks. Check inlet filter isn't clogged. Check nozzle isn't blocked. Turn off engine/motor (just continue h2o on) and pull trigger to release air from system. If none of this works, it may be the unload valve being stuck due to dirt or broken parts. Meet unloader section higher up.

- H2o leaking from connections: First ensure connections are securely fitted. If water is squirting out while pressure washing it is most likely a busted o-band inside the the pressure hose. Contact back up and get them to send new o-ring or hose.

Exist certain to review the summary table to a higher place and double the cheque the make specific support pages before giving up and returning the machine.

Sources

- "Troubleshooting Pressure Washer and Ability Washer Issues." www.PressureWasherTroubleShooter.com

- "Hammer History." Wikipedia.org

- "All Nigh Unloader Valves." world wide web.ePowerWash.com

Source: https://pressurewashr.com/pressure-washer-troubleshooting/

0 Response to "what would cause a power washer motor to overheat"

Postar um comentário